Automatic core shooting machine,Two shooting head. one time can making two sand core.Die Close cylinder forward die close core drawing forward,core box forward, sand feeding valve off, core shooting, sand feeding valve on, air-out, core box backward,consolidation, core drawing backward,die open,unload the sand core, clean dies

Order(MOQ):

1Payment:

TTMarket Price:

$2000Price:

$2000/3000Product Origin:

NANANColor:

GREYShipping Port:

XIAMENLead Time:

15 DAYSAutomatic sand core shooting machine Advantages

Double head heated core box shooter is a heated core box core-making equipment with a four-column operable structure which can be operated manually or automatically.

Compared to common core shooter, advantages of the double head heated core box shooter are as :

1、 High productivity: during the working process of heated core box shooter, sand-filling and compaction are completed simultaneously while the sand core will be immediately hardened in the heated core box. A cycle period only lasts for ten-odd seconds to tens of seconds during which sand core for cast use is produced. (Note: many sand cores can be produced at the same time).

2、 High quality of sand core: sand coreof any complicate level can be shot and with a precise dimension and smooth surface, hence, the casting process redundancy is reduced.

3、 Many assisting equipment and tools used for core-making become unnecessary, such as core drier, core carrier, core rod and strum, etc..

4、 Labor intensity is reduced with flexible and easy operation; temperature can be controlled automatically with electrical heating; favorable conditions are created for mechanization and automation during the core-making process since it is easy to keep the working site clean.

5、 This machine is especially applicable to: dried sand shooting.

The automatic core shooting machine produce sand core with precoated sand, which is suitable for hot core box. The characteristics of the machine is using four guide posts to install the upper and lower die frames, the upper and lower dies are installed respectively on the frames, with precise positioning. The clamping and unclamping are on the same horizontal lever, easy to unload the work pieces. Meanwhile it is equipped with core pulling, suitable for complex products. The machine is widely used in foundry industry, producing sand cores with accurate size and smooth surface. The working principle of the core shooting machine is blow the mixture of sand with solid thermosetting resin as binder to the heated sand core die, the sand core rapidly harden to a certain thickness (about 5~10 mm)in the preheating die, and then the sand cores will be removed, thus finish the quality sand core with smooth surface and accurate size.

|

Contents

|

Parameters

|

|

Dimension

|

1420*680*1700mm

|

|

Net weight of machine

|

513 KG

|

|

Max weigght of sand cores

|

3.2*2 KG

|

|

Max size of core boxes

|

380*280*200 mm

|

|

The longest itinerary clamping

|

≤300mm

|

|

Itinerary of plunger under pressure

|

125mm

|

|

Heating power

|

8kw

|

|

Remarks : According to customers' requirement to add core-pulling at frontal and back.

|

|

Our Service:

Before sales

Our professional technical recommend the right machine,and can also customise special machine as customer's requirement and special parts.

Sales following

During machine production, watching the machine quality and testing machine.and take pictures or make video for customer checking.

After Sales

We will send technical go to customer's factory to install and adjust machine.

We have after-sell service to supply all life-time machine maintance and repairment service.

FAQ:

Q: Are we a trading firm or a manufacturer?

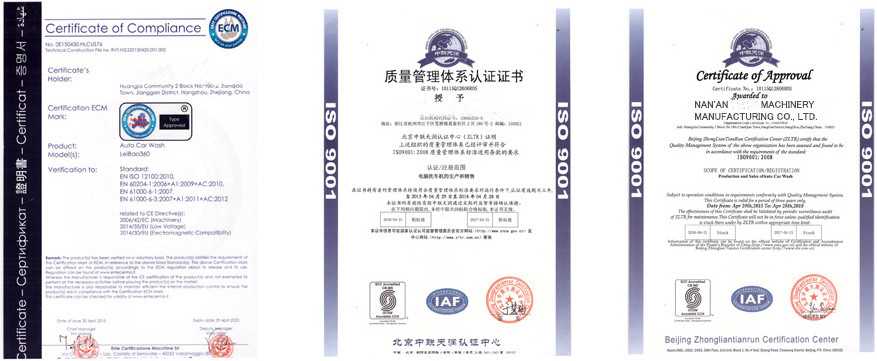

A: We are a MANUFACTURER.

Q: What’s our payment mode?

A: L/C, T/T

Q: Can machines be customized?

A: YES.

Q: How long is the warranty period?

A: 12 months.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 D&S Automatic Co.,Ltd.. All Rights Reserved.

IPv6 network supported