Why choose us

About UsD&S Automatic Co.,Ltd. ,located at the China plumbing town of Fujian Nan'an,It is a professional machine company. We supply you modern facilities,such as faucet, valve, brass fitting, cartridge, brass fittings, teflon tape and all kinds of machines. Our major service are manufacturing, sourcing, production, sales and service which includes engineer training in your factory . We sold to China, India, Brazil, Iran, Pakistan, Bangladesh, Prussian, Turkey,Uganda,Algeria, etc. Warmly welcome to visit our factories. Call us or mail us, thank you! Quality Control & Certificate All of our products R&D process and production process is strictly following the ISO9001:2008 policy. Our products Our main product range including : Complete Faucet Making Machine Valves Machine Production line Fire Sprinkler Processing Devices Teflon Tap Machine Production Line Brass Spindle/Brass Fitting Making Machine Polishing Machine Testing Machine Assemble Machine

1898

1898

Corporate History

1000

1000

Global Installation

10

10

Projects Reference

100

100

Global Partners

Our main products

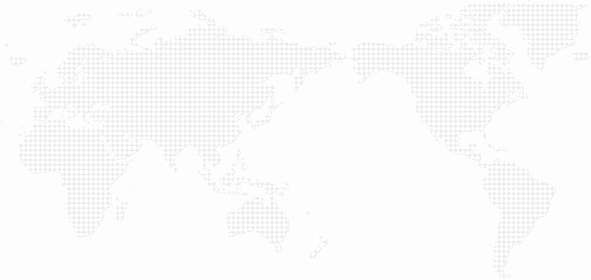

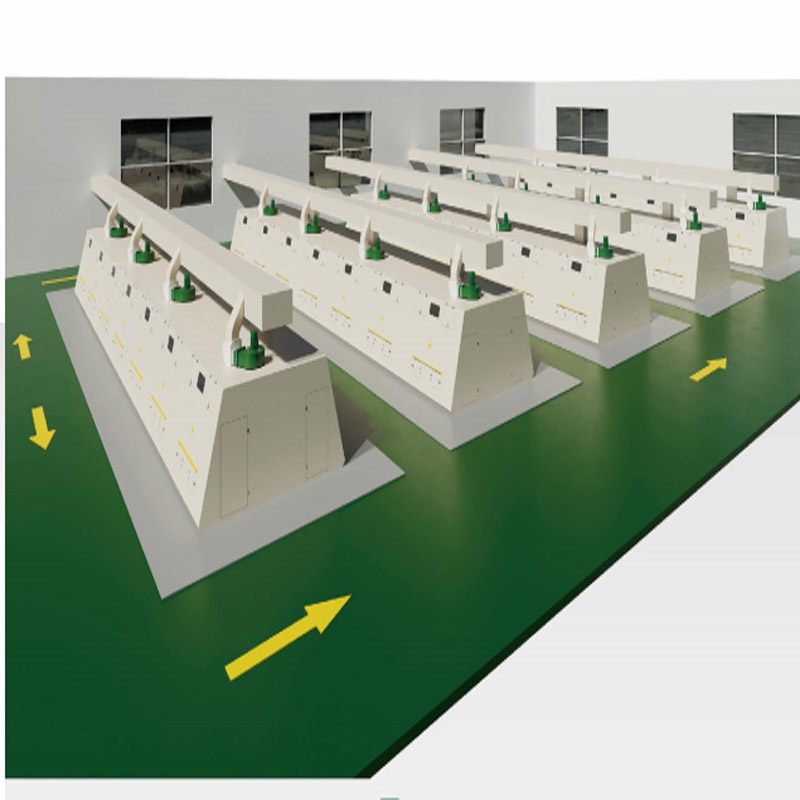

Product CategoryWelcome you to choose us as your professional faucet production line project .Our team will give you support from A- Z, from raw material to finish products . it is not just sellling machines( resin sand---mix machine---moulds---core shooting machine--- process machine ---polish machine ---chrome plate--- assembling machine---testing machine ---packing /delivery , it is long time coopreation with technical supporting.Our team will be there for you . Guarantee you produce good products.

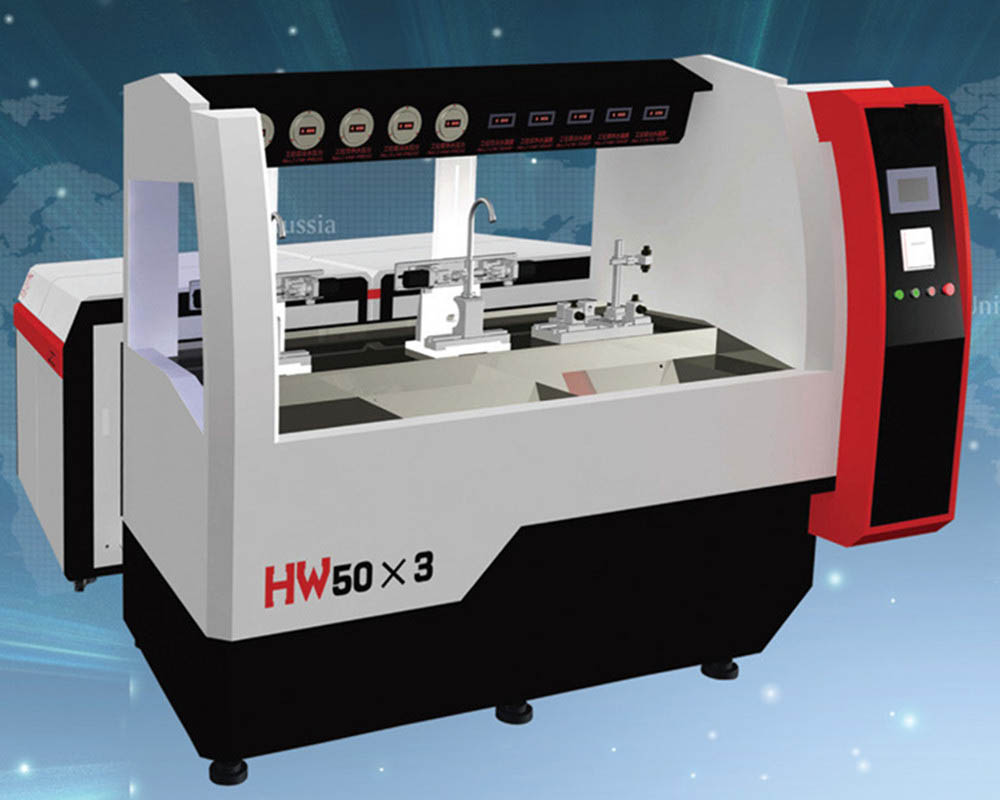

Seven spindle automatic cnc lathe machine One time can finish angle valve body, concealed stop valve body, ball valve ,etc. Full automatic, high precision. high effectifficy .

semifinished product processing equipment,plug processing equipment,glass ball assembly machine,plug oring assembly machine,press tester.Fire sprinkler manufacturing devices.

We supply completed teflon tape production line. from ptfe powder to finish products. Our machine is sold to 90% teflon tape factory in China, and also sold to india, bangladesh, etc. quality is very good and stable. We give engineer to start machines to produce in your factory . And guarantee you can produce well. welcome come to visit !

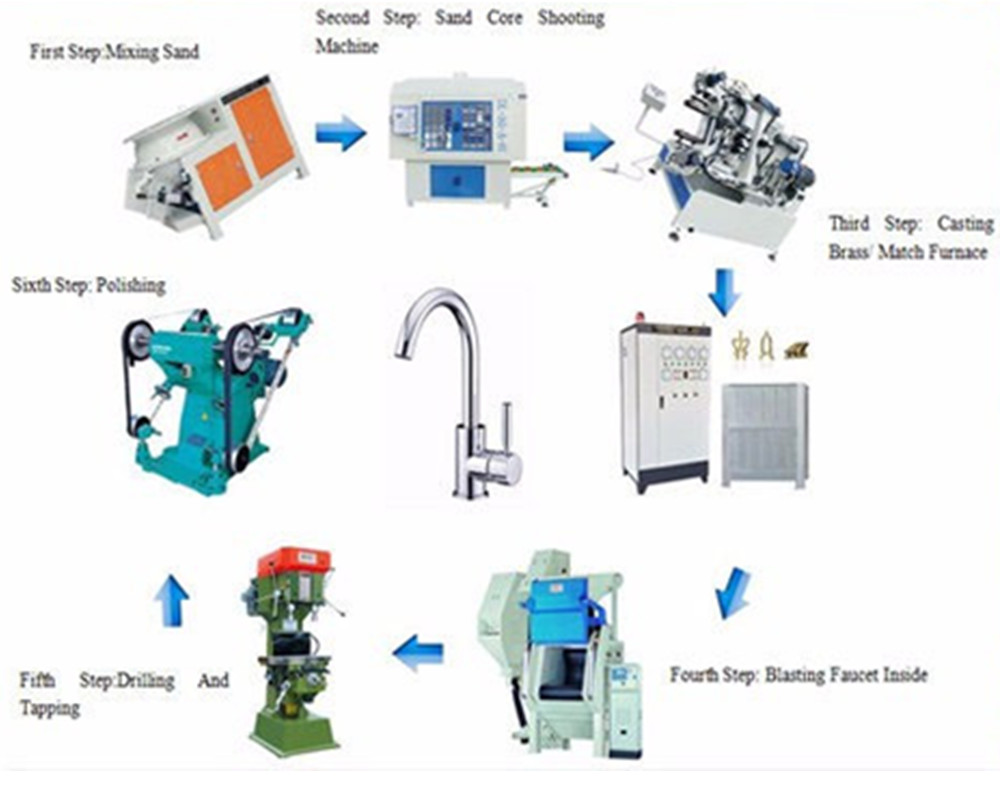

1. From Brass bar cutting machine to cut into small pcs. 2. Using autmatic lathe machine( full/manual) to process the thread, groove. etc. 3. Using hex machine to make the hex. We will make machine tools ,clampers according to your sample, and test machine ready for you. give samples for you confirm.

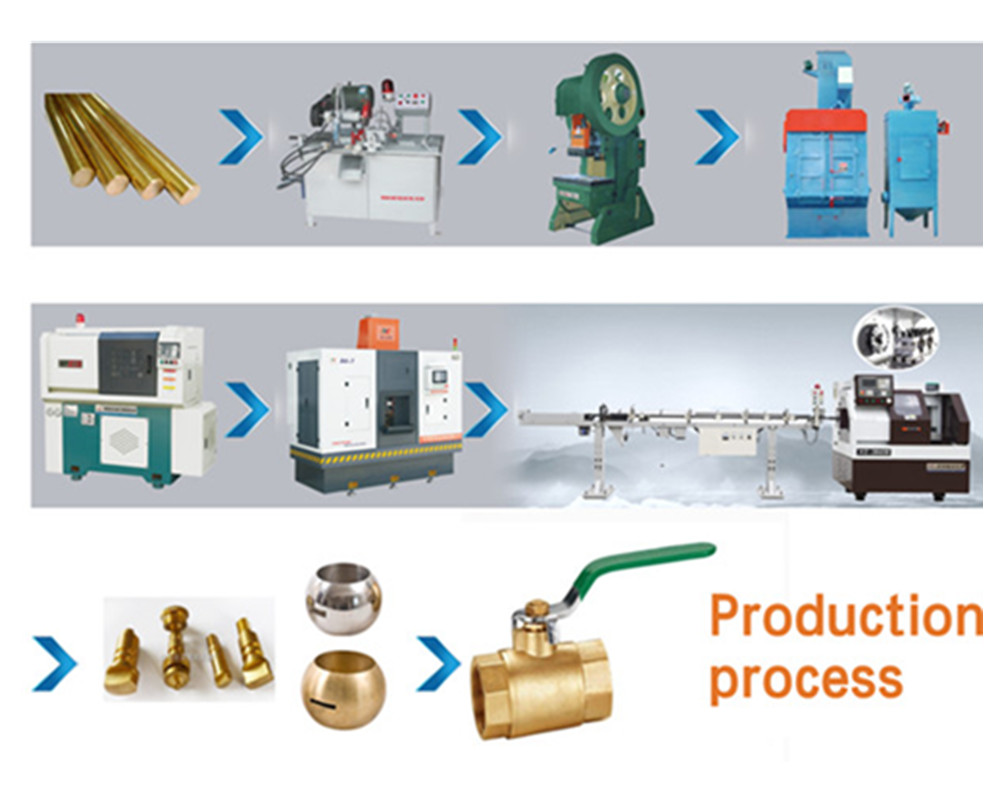

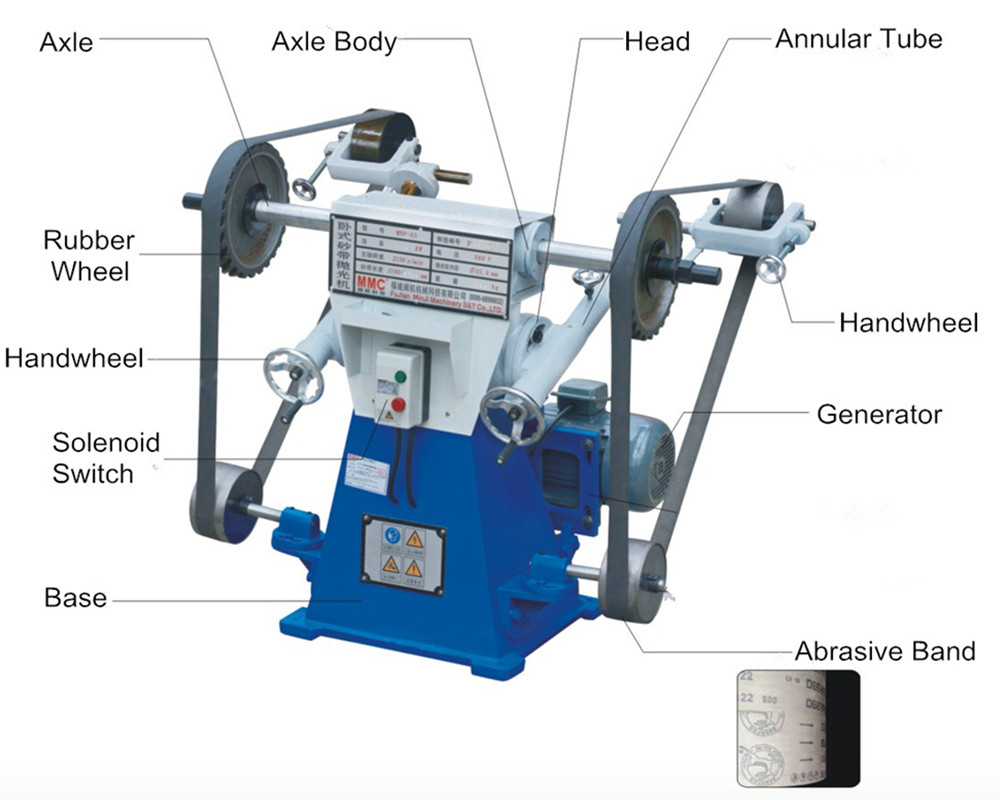

Use on the hardware’s surface of copper, stainless steel, aluminum, zinc and other materials to grind and polish. By changing abrasive belts with different width and particle size according to the work piece’s toughness and smoothness, you can process your work piece quickly and precisely. It can also use with rubber wheel, cloth wheel and grinding wheel. Low working noise and power demand, easy and safe to use. Environment-friendly design prevents outgoing air flow and dust. Easy-to-clean and space-smart dust removal system can reach 95% de-dust level, ideal for dust control and recycle.

Thermostatic Fancets Comprehensive Tester

Welcome you to choose us as your professional faucet production line project .Our team will give you support from A- Z, from raw material to finish products . it is not just sellling machinesit is long time coopreation with technical supporting.Our team will be there for you . Guarantee you produce good products.

Our main products

Hot ProductOur news

latest News1. The cutting and rewinding machine should process the entire roll or sheet of raw materials in the fixed-length cutting process, such as plastic packaging materials, packaging cartons, steel plates, films, leather and wood cutting, all of which should adopt the fixed-length cutting process. 2. The cutting length can be set continuously. If there is an error in the actual cutting length, it can be calibrated by setting parameters. 3. The cutting control of the slitting and rewinding machine is divided into two types: static and dynamic cutting: set the desired length downward, then static slitting, and restart after the cutting operation; when the set length is reached, the slitting machine stops the signal The dynamic cutter is sent to cut material during movement. Structural advantages of slitting and rewinding machines: There is a paper tube processing spindle in the middle of the slitting and rewinding machine. The front end of the spindle is fixed on the base with a set of bearings, and a pulley is installed in the middle of the set of bearings; a compression cylinder is installed near the base, and a compression cylinder is installed on the upper end of the cylinder's support rod. Set support rod bearings to support the spindle. The slitting and rewinding machine is attached to the surgeon at the upper end of the shaft and is provided with multiple blades on it and arranged according to a certain gap; a main blade shaft support frame is also provided on the top of the slitting and rewinding machine, The support tube of the support frame is attached to the middle. The structural advantages of the slitting and rewinding machine fill the technical gap of the automatic pipe cutting machine. Choose D & S Automatic, we will provide you with the best service.

D&S Technology Co,Ltd CNY Holiday Notice Holiday is around the corner. Our office will be closed between Feb 5th to Feb 18th. lf any issues please send mail ([email protected])to me or call my mobile at +86-13600706701 (Wechat&Whatsapp same number). Best wishes.

Engraving and milling machines generally use a gantry structure. The gantry type is divided into pillar type and fixed beam type. At present, most engraving and milling machines are of the fixed beam type. It can be engraving or milling. On the basis of the engraving machine, the power of the spindle and servo motor is increased, and the bed capacity is increased, while maintaining the high speed of the spindle and, more importantly, high precision. Engraving and milling machines are also developing at high speeds. They are generally called high-speed machines. They have stronger cutting capabilities and very high processing accuracy. They can also directly process materials with a hardness above HRC60. They can be formed in one go and are suitable for finishing. The engraving and milling machine requires a high-speed CNC system with a spindle speed of about 3000~30000RPM. CNC milling and machining centers are processing equipment used to complete larger milling volumes of workpieces. CNC engraving and milling machines are used to complete smaller milling volumes or soft metal processing equipment. High-speed cutting machine tools are used to complete medium milling volumes and reduce the amount of polishing after milling to processing equipment. Choose D & S Automatic, we will provide you with the best service.

D&S Technology Co,Ltd Holiday Notice Holiday is around the corner. Our office will be closed between Dec 30th to Jun 1st. lf any issues please send mail ([email protected])to me or call my mobile at +86-13600706701 (Wechat&Whatsapp same number). Best wishes.

Copyright © 2024 D&S Automatic Co.,Ltd.. All Rights Reserved.

IPv6 network supported