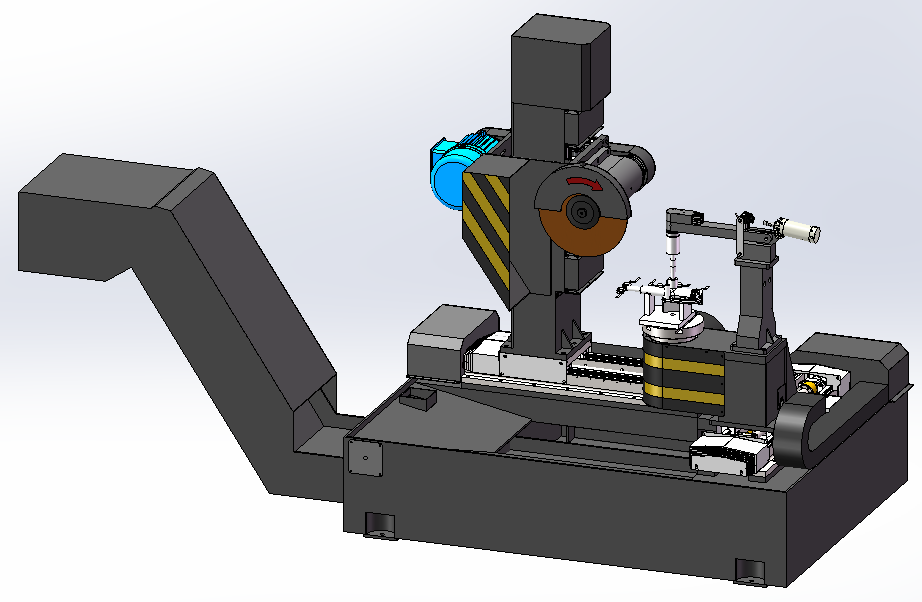

In the fast-evolving world of manufacturing, precision, versatility, and efficiency are key to maintaining a competitive edge. The 14K axis vertical rotary combined machine tool is a groundbreaking solution designed to meet the increasing demands of complex machining operations. This innovative equipment integrates advanced technology to offer unparalleled performance in industries such as automotive, aerospace, and electronics. One of the standout features of the 14K axis vertical rotary combined machine tool is its ability to combine multiple machining functions into one seamless operation. Whether it’s milling, turning, or grinding, this machine can handle it all with exceptional accuracy. The addition of a rotary axis further enhances its capabilities, allowing for more intricate and efficient part production, especially in high-precision environments. 1: 14K Axis Vertical Rotary Combined Machine Tool The 14K axis vertical rotary combined machine tool is engineered to reduce setup time and improve cycle efficiency. With its vertical orientation, the machine provides better chip removal and a stable cutting environment. This design minimizes the chance of vibration, ensuring a smooth operation even under heavy cutting conditions. Furthermore, the machine's high-speed spindle offers rapid tool changes and greater throughput, helping manufacturers meet tight production schedules. 2: High-Precision CNC Machinery High-precision CNC machinery is at the core of modern manufacturing, and the 14K axis vertical rotary combined machine tool excels in this area. Featuring a robust CNC system, it guarantees precise control over each machining operation. The highly accurate motion control and feedback loops ensure that every component produced meets the highest standards, even for complex geometries. 3: Multi-Function Machining Equipment As a versatile piece of equipment, the 14K axis vertical rotary combined machine tool serves as a multi-function machining equipment, allowing businesses to streamline their operations by reducing the need for multiple machines. This not only cuts down on floor space but also simplifies the workflow, boosting overall productivity. With its easy-to-use interface and customizable features, operators can quickly adapt to different production requirements, reducing downtime and maximizing machine uptime. In addition to the impressive features of the product itself, the DS brand offers outstanding service advantages that set it apart in the competitive market. With a reputation for reliability, DS provides comprehensive technical support and training to ensure seamless integration into your existing production line. From fast response times to expert troubleshooting, DS’s customer-first approach ensures your investment in the 14K axis vertical rotary combined machine tool delivers long-term value. By choosing DS brand and the 14K axis vertical rotary combined machine tool, you are not only investing in superior technology but a...

Drawing machine is also known as wire drawing machine, drawing machine, wire drawing machine English name is drawing machine, is a widely used in industrial applications of mechanical equipment, widely used in machinery manufacturing, hardware processing, petrochemical, plastic, bamboo and wood products, wire and cable and other industries. Drawing machine according to its use can be divided into metal drawing machine (used for standard metal products production preprocessing), plastic drawing machine (used for plastic products industry in polyester, nylon, polyethylene, polypropylene, polyester slice as raw materials of hollow, solid round silk or flat silk processing of special complete sets of equipment), bamboo drawing machine (used for bamboo products industry make chopsticks, toothpick, barbecue sticks pull bamboo, wood reprocessing special equipment), etc. Metal wire drawing machine Belongs to the standard and other metal products production preprocessing equipment, the purpose is to transport by the steel manufacturer production to the standard metal products production enterprises of wire or rod after wire drawing machine pull processing, the wire or rod diameter, roundness, internal metallographic structure, surface finish and straightening are standard metal products production needs such as raw material processing requirements. Therefore, the pretreatment quality of wire drawing machine for wire or bar is directly related to the product quality of standard parts and other metal products production enterprises.wire drawing machine belongs to metal products equipment industry metal wire drawing machine, drawing machine is widely used in the production of steel wire, rope wire, prestressed wire, steel wire, standard parts and other metal products. Plastic drawing machine The main feature of the product is the drying-free exhaust energy-saving plastic drawing machine is that the exhaust port is provided on the material cylinder, and the material cylinder is connected by at least two sections. The pitch of the screw in the first material cylinder is different from the rear. It does not need the plastic mixer to stir, and can absorb the moisture produced in the plastic mixing. The plastic wire pulled is uniform and smooth, not easy to break the wire, and has high working efficiency and less energy consumption. D&S Provides you with professional and high-quality products.

Function and features of the single-station CNC sawing equipment 1. The single-station CNC sawing machine is mainly used for the pouring outlet separation of copper, aluminum and zinc castings; 2, a clip, can achieve multi-faceted multi-angle saw-cut; 3, the use of CNC system control, fast moving speed, accurate position; 4, programming using teaching programming, easy to learn and easy to use; 5, a product only needs to be programmed once, and the second processing can be directly called; 6, the saw blade using vortex pipe cooling, high cooling efficiency; 7. saw blade life: our customer actual use feedback, each saw blade can be cut about 10000 knives each time, the saw blade can be repaired and used twice, which is related to the size of the gate. 8, the loading and unloading safety door installed plexiglass, the front door using cylinder automatic switch door. D&S Provides you with professional and high-quality products.

Our holiday period is from May lst to May 5th, 2024 April 28 and May 11 will be adjusted as working days. If you want to inguire about our products, you are welcome to send mail ([email protected])to me or call my mobile at +86-13600706701 (Wechat&Whatsapp same number). and we will reply to you as soon aspossible. D&S Provides you with professional and high-quality products. We are committed to providing you with best solution that best suits you.

1. The cutting and rewinding machine should process the entire roll or sheet of raw materials in the fixed-length cutting process, such as plastic packaging materials, packaging cartons, steel plates, films, leather and wood cutting, all of which should adopt the fixed-length cutting process. 2. The cutting length can be set continuously. If there is an error in the actual cutting length, it can be calibrated by setting parameters. 3. The cutting control of the slitting and rewinding machine is divided into two types: static and dynamic cutting: set the desired length downward, then static slitting, and restart after the cutting operation; when the set length is reached, the slitting machine stops the signal The dynamic cutter is sent to cut material during movement. Structural advantages of slitting and rewinding machines: There is a paper tube processing spindle in the middle of the slitting and rewinding machine. The front end of the spindle is fixed on the base with a set of bearings, and a pulley is installed in the middle of the set of bearings; a compression cylinder is installed near the base, and a compression cylinder is installed on the upper end of the cylinder's support rod. Set support rod bearings to support the spindle. The slitting and rewinding machine is attached to the surgeon at the upper end of the shaft and is provided with multiple blades on it and arranged according to a certain gap; a main blade shaft support frame is also provided on the top of the slitting and rewinding machine, The support tube of the support frame is attached to the middle. The structural advantages of the slitting and rewinding machine fill the technical gap of the automatic pipe cutting machine. Choose D & S Automatic, we will provide you with the best service.

D&S Technology Co,Ltd CNY Holiday Notice Holiday is around the corner. Our office will be closed between Feb 5th to Feb 18th. lf any issues please send mail ([email protected])to me or call my mobile at +86-13600706701 (Wechat&Whatsapp same number). Best wishes.

Engraving and milling machines generally use a gantry structure. The gantry type is divided into pillar type and fixed beam type. At present, most engraving and milling machines are of the fixed beam type. It can be engraving or milling. On the basis of the engraving machine, the power of the spindle and servo motor is increased, and the bed capacity is increased, while maintaining the high speed of the spindle and, more importantly, high precision. Engraving and milling machines are also developing at high speeds. They are generally called high-speed machines. They have stronger cutting capabilities and very high processing accuracy. They can also directly process materials with a hardness above HRC60. They can be formed in one go and are suitable for finishing. The engraving and milling machine requires a high-speed CNC system with a spindle speed of about 3000~30000RPM. CNC milling and machining centers are processing equipment used to complete larger milling volumes of workpieces. CNC engraving and milling machines are used to complete smaller milling volumes or soft metal processing equipment. High-speed cutting machine tools are used to complete medium milling volumes and reduce the amount of polishing after milling to processing equipment. Choose D & S Automatic, we will provide you with the best service.

D&S Technology Co,Ltd Holiday Notice Holiday is around the corner. Our office will be closed between Dec 30th to Jun 1st. lf any issues please send mail ([email protected])to me or call my mobile at +86-13600706701 (Wechat&Whatsapp same number). Best wishes.

Copyright © 2026 D&S Automatic Co.,Ltd.. All Rights Reserved.

IPv6 network supported