Each machine has to pass the checklist of the machine precision before shipment

Item NO.:

ES30HOrder(MOQ):

1Payment:

TT/LCProduct Origin:

CHINAColor:

GREYShipping Port:

NINGBOLead Time:

30 DAYSLine Rail CNC Machine Tool

Each machine has to pass the checklist of the machine precision before shipment

1 Adjust levelness of the machine

2 Straightness of rise and fall mechansim in vertical movement

3. Verticality of the operating platform surface to the guide track surface of the column

4. Straigtness of the datum T-slot of the operating platform

5. Plainness of the operating platform surface

6. Oscillation of the spindle end

7. Circular run ou of the spindle bore-hole axis

8. Parallelism of the rotaryaxis of the spindle to the operating platform

9. Verticality of the rotary axis of the spindle to the operating platform

10. Parallelism of the longitudinal movement of the operating platform to the datum”T“-shot

11. Vertically of the transverse movement to the longitudial movement of the operating platform

12. Parallelism between the movement and the surface of the operating platform

|

Beijing KND CNC system |

s |

|

AC Servo system |

s |

|

Pneumatic spring perch |

s |

|

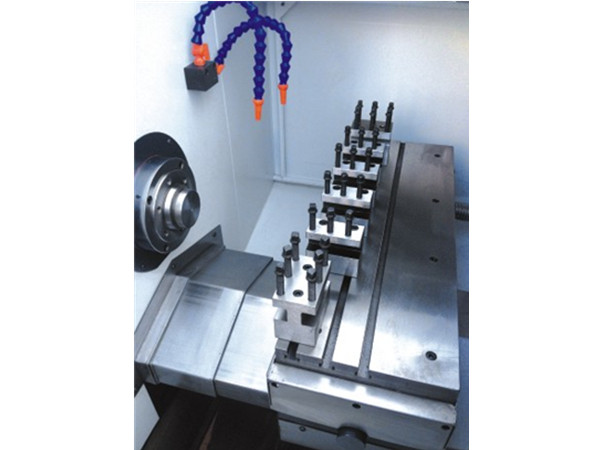

Tool carriage |

s |

|

4kw/5.5kw spindle motor |

s |

|

Stepless speed regulation spindle |

s |

|

Automatic lubrication |

s |

|

Thread function of metric /british standard |

s |

|

Cooling system |

o |

|

Four -workstation automatic tool turret |

o |

Maximum revolution diameter of bed

mm

380

Maximum revolution diameter of excess carriage

mm

180

Maximum top margin

mm

-

Maximum Z-axle stroke

mm

360

Maximum X-axle stroke

mm

550/600

Rapid travel speed

mm/min

x:12 z:18

Diameter of spindle through hole

mm

48

Power of main motor

kw

4

Rotation speed of spindle

r/min

200-3000

Sectional area of cutter arbor

mm

20x20

Stroke of tailatock sleeve

mm

-

Taper of sleeve bore

mt

-

Chuck specification

mm

160/200

Positioning accuracy

mm

x;0.01 z:0.01

Pulse equivalent

mm

x:0.005 z:0.01

Cooling water pump

w

90

Weight of machine tool

kg

1500

Contour dimension of machine tool (L*W*H)

mm

1718x1175x1600

Our Serviece:

Before sales

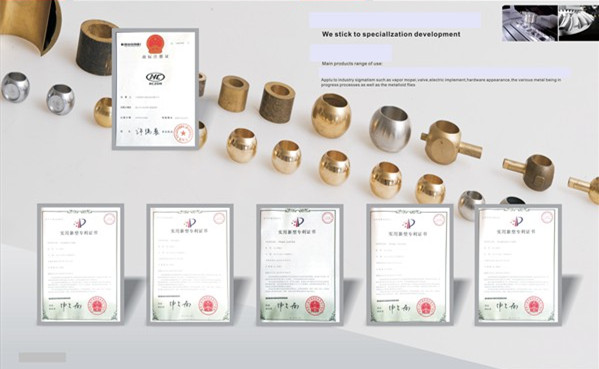

Our professional technical recommend the right machine,and can also customise special machine as customer's requirement and special parts.

Sales following

During machine production, watching the machine quality and testing machine.and take pictures or make video for customer checking.

After Sales

We will send technical go to customer's factory to install and adjust machine.

We have after-sell service to supply all life-time machine maintance and repairment service.

FAQ:

Q: Are we a trading firm or a manufacturer?

A: We are a MANUFACTURER.

Q: What’s our payment mode?

A: L/C, T/T

Q: Can machines be customized?

A: YES.

Q: How long is the warranty period?

A: 12 months.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2026 D&S Automatic Co.,Ltd.. All Rights Reserved.

IPv6 network supported